Why Cement-Lock™?

A Proven Technology

The Cement Lock technology was developed for the EPA and U.S. Army Corps of Engineers. A pilot program was launched in Bayonne, NJ, using toxic material from the Passaic River. The technology was further refined by Volcano Partners and the global engineering firm of Wood Group. Besides Ecomelt being manufactured, electricity is also produced to provide power to the local community.

People are at risk of exposure to toxic materials in their local environment. Hazardous materials management typically involves transporting toxic materials from one location to another, buried out-of-sight or placed in a landfill with on-going liabilities, until it is a challenge for the next generation. Or, hazardous material is spilled or illegally dumped with immediate environmental and health consequences.

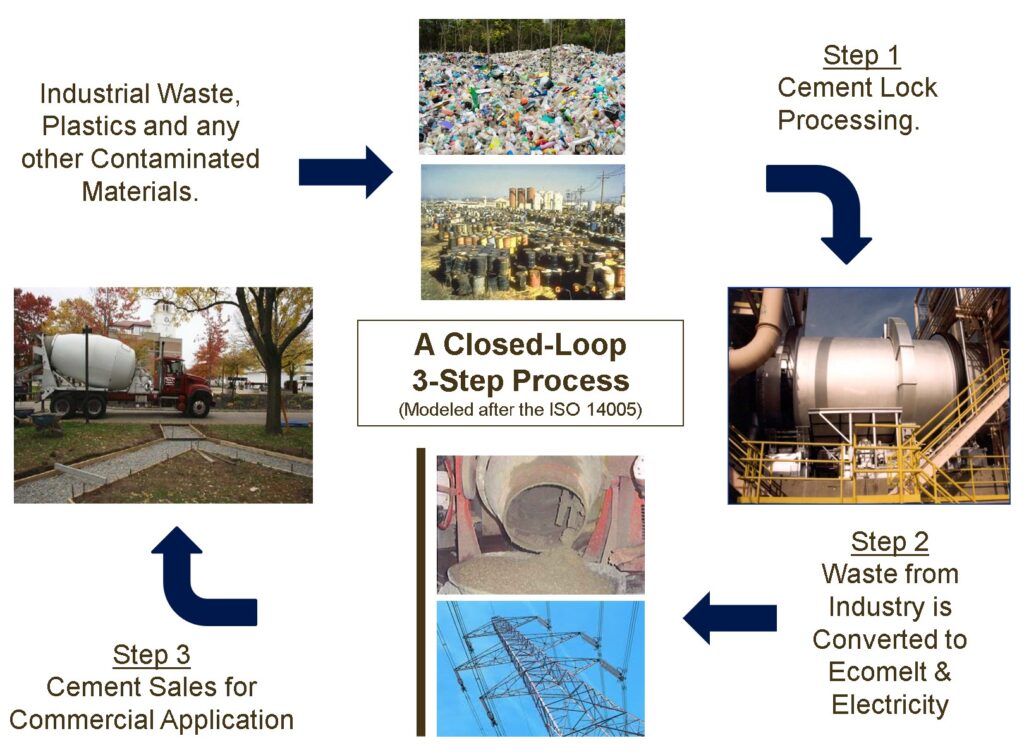

ABOUT THE PROCESS

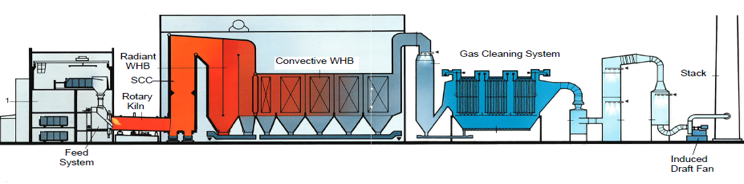

Cement-Lock™ is a versatile, cost-effective, and environmentally friendly manufacturing technology for producing construction-grade cements from a wide variety of contaminated waste materials, such as sediments, Superfund sites, sludges, chemical wastes, petroleum refinery wastes, and incinerator residues. Organic and inorganic contaminants are present in these wastes across a broad range of concentrations. Through the Cement-Lock process, contaminated materials and proprietary modifiers are fed to a reactive melter operating under highly specialized conditions where all the organic compounds are completely destroyed. Chlorine and sulfur compounds are sequestered and heavy metals are immobilized within the molten matrix.

During processing, the melt (EcoMelt™) is imparted with latent cementitious properties that allow it to be transformed into construction-grade cement. The Cement-Lock Technology is unique because it not only decontaminates the hazardous materials but also converts them into a beneficial commercial commodity, namely, construction-grade cement.